Casting, Machining and Finishing—Under One Roof

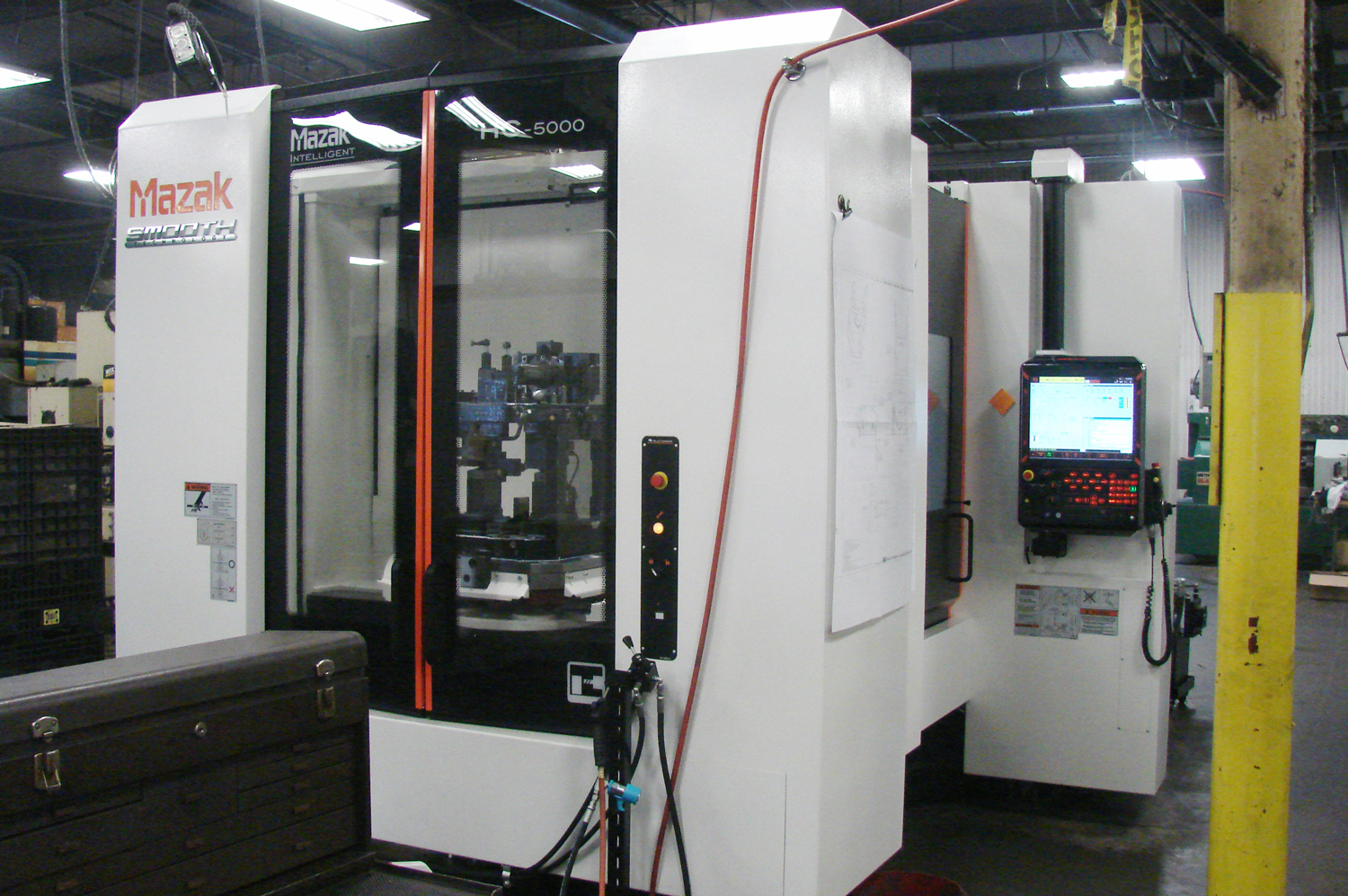

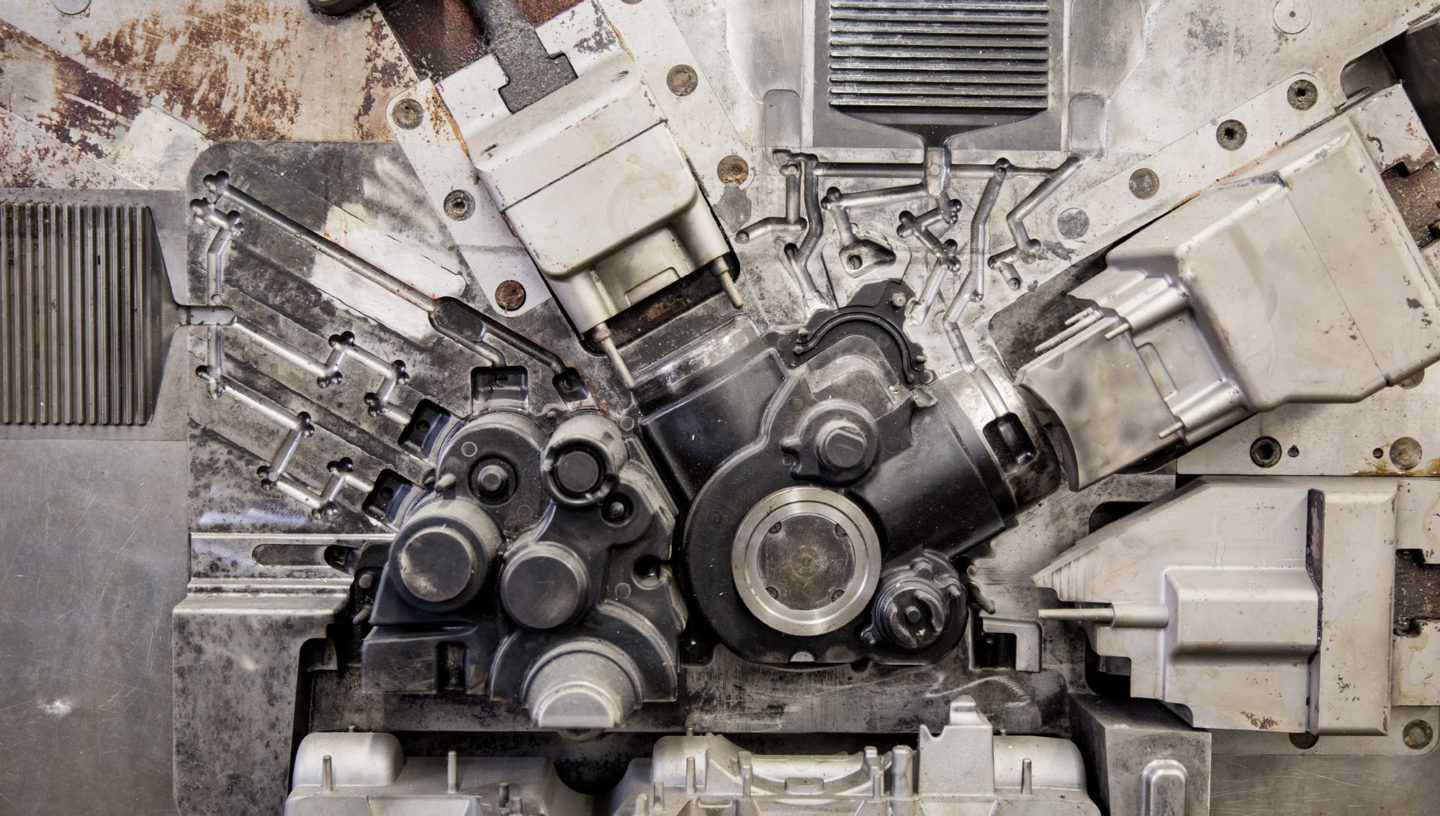

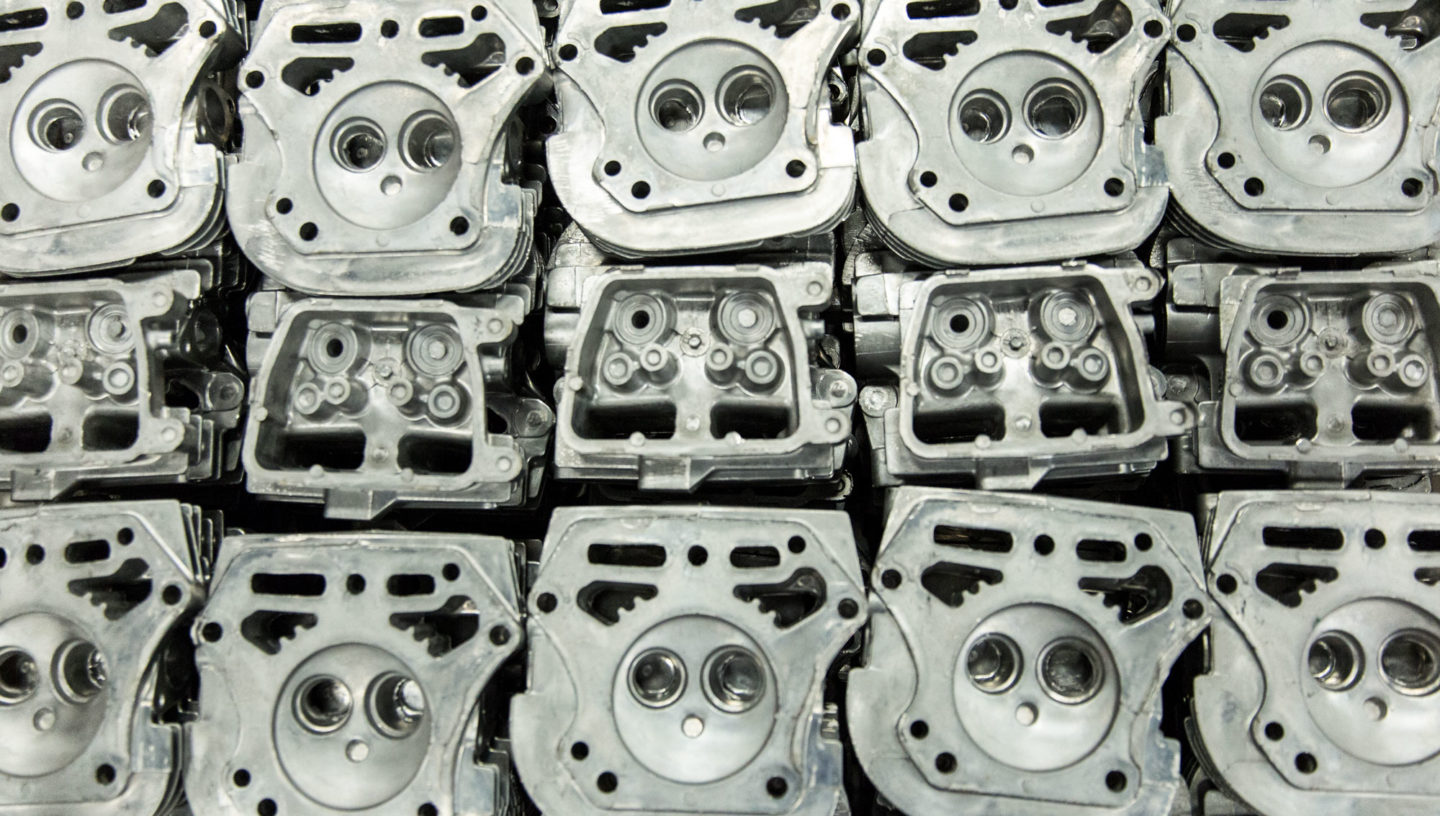

At Kurt Die Casting we produce complex, high-quality aluminum and zinc-aluminum alloy die castings for a wide range of industries. With over 100,000 square feet manufacturing space, we have the capacity and capabilities for large castings and CNC machining. Today we have over 25 modern casting machines ranging in size from 500 to 1,200 tons and the capability to machine, finish and assemble our castings to meet even the most challenging design requirements. We take pride in using our experience and technology to produce castings with complex geometries and stringent porosity requirements using a wide range of casting alloys. Our rapidly growing CNC-machining department uses the latest technology to machine features to very tight tolerances. All of this adds up to achieving our ultimate goal: Providing the best possible products, value and service to our customers.

When it comes to superior die casting, look to Kurt Manufacturing to deliver. It is our mission to create high quality, competitively priced products that are delivered on time and above all expectations. This dedication to excellence is how we’ve been able to create an extremely loyal customer base.

Request a quote for the diecast aluminum, or contact Kurt Die Casting for more information.

The Kurt Advantage

- Precision aluminum castings, from <1 pound up to 26 pounds

- 360, 380, and 390 aluminum alloys

- ZA 27 aluminum zinc alloy

- Design for manufacturability and early design support

- CAD compatibility for web-based communication and fully interactive manufacturing

- Complete part solution—casting, machining, and finishing—all under one roof

- Advanced, proprietary closed-loop shot control system

- Dendrite control and measurement capabilities

- Commitment to quality and exceeding customer expectations

- In-house tool building

- Rapid lead times

- Serving international customers all around the world

Tour Kurt Die Casting